Products

Solutions

Retail & eCommerce

Defense

Logistics

Autonomous Vehicles

Robotics

AR/VR

Content & Language

Smart Port Lab

Federal LLMs

Resources

Company

Customers

See all customersPonce, Puerto RicoOpen Now

AI Smart Port Lab

Empowering port operators with AI to improve working conditions, decrease costs, and increase throughput.

Port of Ponce

Scale Upgrades the Port of Ponce

Scale’s Smart Port Lab is being built in the Port of Ponce, Puerto Rico.

What is Scale doing for the Port of Ponce?

Scale is building a Smart Port Lab where AI-enabled infrastructure will be researched, built, and exported to shipping ports globally. The Smart Port Lab will feature autonomous inspection systems, container identification and tracking, AI-powered document processing, drive-by-wire cranes and bomb carts, and advanced surveillance.

Why the Port of Ponce?

The Port of Ponce was recently hit by a series of natural disasters, including the 2020 earthquakes, Hurricane Maria, and, most recently, Hurricane Fiona. Scale’s investment to establish a Smart Port Lab at Port Ponce is an opportunity to bring global shipping and logistics customers to the local area, increase port activity, and aid in the economic revitalization of the city of Ponce.

How will Scale build the Smart Port?

Scale is partnering with the Ponce Port Authority and investing more than $2 million to transform the Port of Ponce from a FEMA designated disaster site to a Smart Port Lab. AI-enabled Smart Port infrastructure and technology augments workers’ capabilities, enhances operational processes at the port, and modernizes shipping and transportation equipment where innovation has traditionally been stagnant.

How the Port Will Operate

AI to Automate and Augment Your Operations

Smart Port Lab

How Scale is Building the Smart Port Lab in Ponce

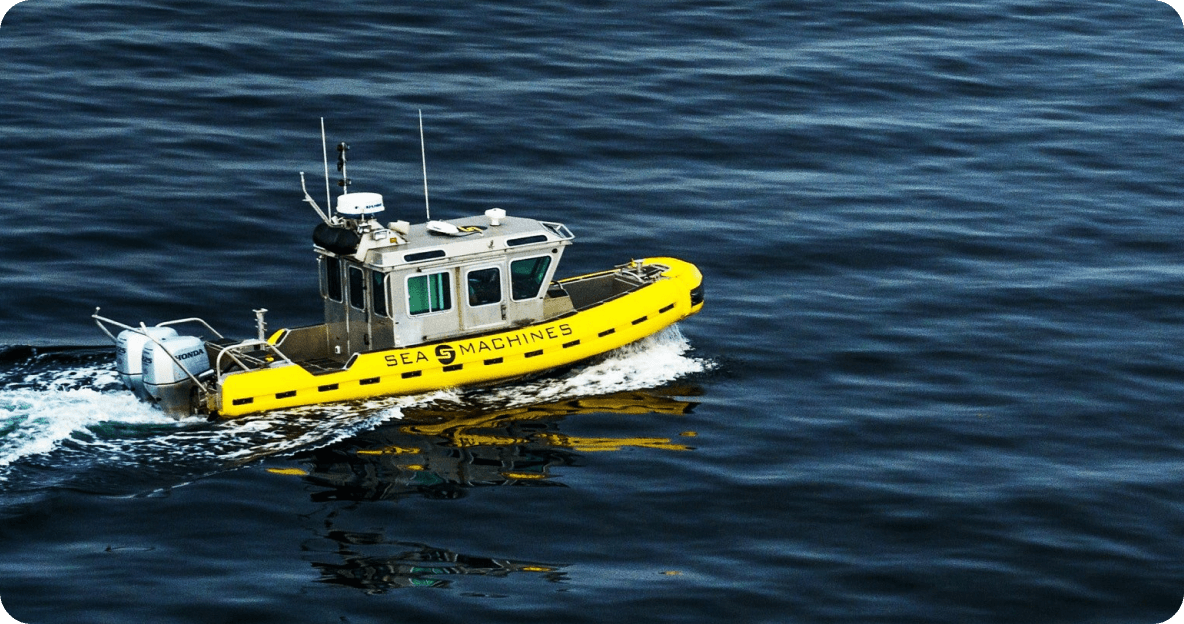

Autonomous Inspection System

Scale’s autonomous inspection system automatically deploys and operates, minimizing hardware downtime and accelerating container inspection. Scales advanced computer vision models ensure fast and accurate inspections.

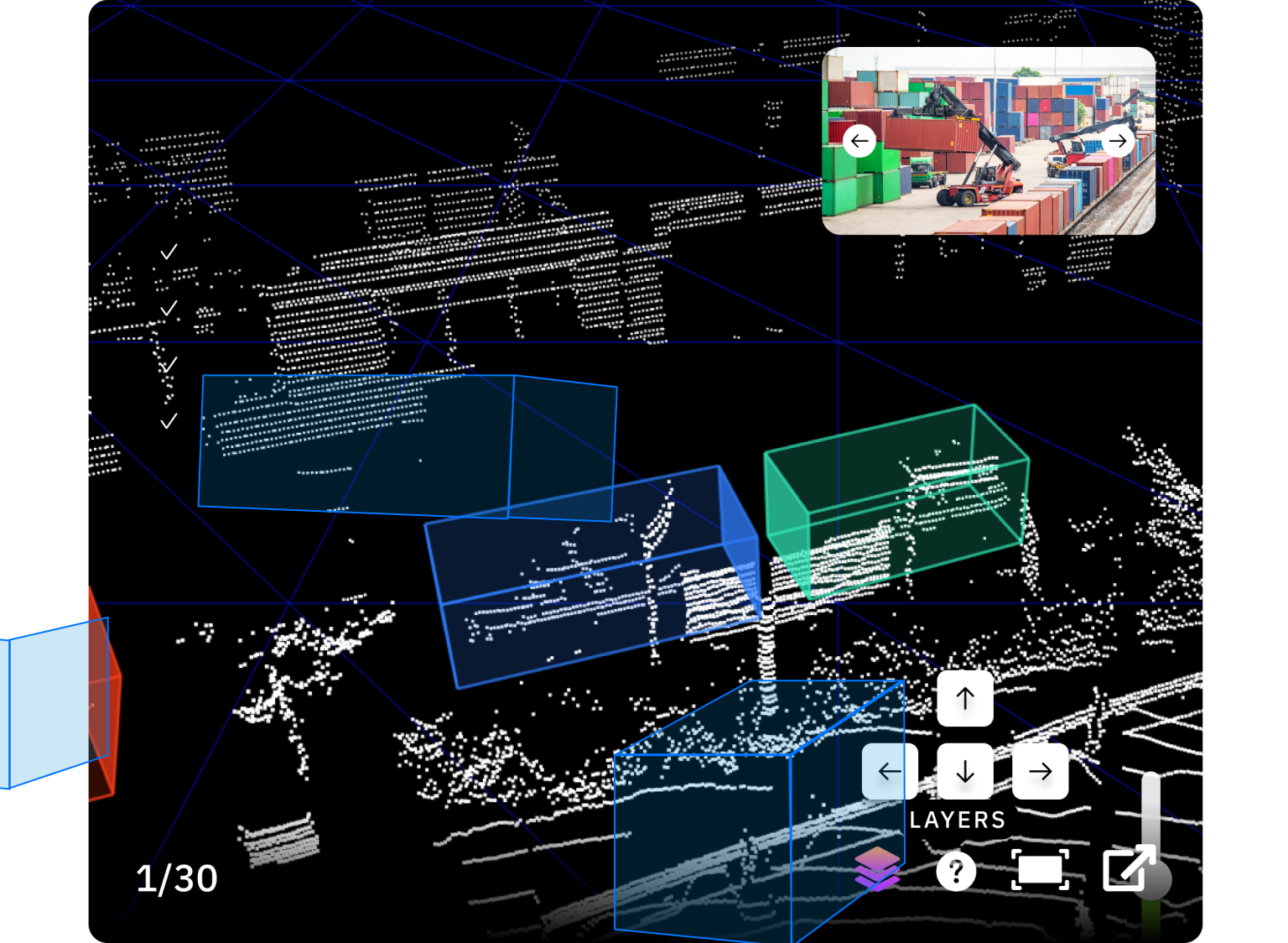

Digital Receipt Registry

Every stage of container movements is documented using camera systems and computer vision, OCR, and custom logic. The Digital Receipt Registry confirms and verifies container movements, allowing ports to improve throughput, cut down on inventory discrepancies, and reduce insurance costs.

Level 1 Hardware Autonomy Kit

Scale’s level 1 autonomy kits enable operators so they can maneuver STS, gantry cranes, and bomb carts from remote locations with the assistance of additional sensors, cameras, and augmented reality annotations to safely increase productivity.

Computer Vision (CV)-Assisted Surveillance

Scale’s CV-assisted surveillance provides automated detection and tracking of every person, vehicle, and piece of equipment on your port.

Case Studies

Scale is Trusted by World Class Companies

Why Scale

Scale Combines Model-based and Human-in-the-loop Techniques to Ensure High-quality Data

Multimodal Intelligence

Leverage all available data from drones, stationary cameras, and other sensors to have a 360-degree view of the entire port. Advanced 3D sensor fusion technology allows you to combine camera, video, LiDAR, and RADAR data into a single view.

Human + Machine Synthesis

We augment human capabilities with drive-by-wire cranes and carts make your workforce more efficient, while providing a more comfortable working environment.

Autonomous Tracking & Inspection

Scale’s autonomous tracking system uses drones with advanced computer vision capabilities to navigate your port, identify and track containers, and scan equipment on your port for damage. Your workforce no longer has to manually track containers or climb cranes to perform damage inspections.